Cross Linked Polyethylene water tubing, or PEX, is a relatively new product which was first introduced in North America in 1984. PEX has been primarily used for radiant floor heating, and more recently water distribution systems. If you look at any new construction houses, this is probably what you’ll find supplying water throughout the home. If you have any plumbing projects coming up, I recommend using PEX. Here’s why:

Cross Linked Polyethylene water tubing, or PEX, is a relatively new product which was first introduced in North America in 1984. PEX has been primarily used for radiant floor heating, and more recently water distribution systems. If you look at any new construction houses, this is probably what you’ll find supplying water throughout the home. If you have any plumbing projects coming up, I recommend using PEX. Here’s why:

Ease of installation My favorite feature of PEX tubing is its ease of installation. I’ve soldered plenty of copper tubing, and it’s a time-consuming, pain-in-the-butt process. Every length of tubing needs to be perfectly measured, cut, reamed, fluxed, and soldered. I get flux all over myself, I usually end up burning myself on a piece of copper that I forgot was hot, and much care needs to be taken to make sure the torch doesn’t burn other materials in the home.

With PEX, all of this hassle is eliminated. Because PEX is so flexible, you typically only need to eyeball the length of the tubing before cutting it, and the fittings are quite easy to join together – much easier than soldering. The first time I installed PEX tubing it was so easy and so fast that it felt like I was cheating. Plumbing isn’t supposed to be this easy.

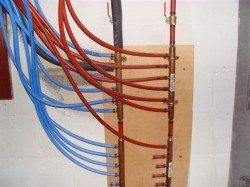

Better water flow Instead of running large branch lines through the house and tapping off the branch lines with smaller lines to feed bathrooms, kitchens, and other rooms, PEX can be configured in what’s referred to as a ‘Home Run’. This is done by installing a large manifold in the basement near where the water comes in to the house, and then running a separate water supply tube to every single plumbing fixture. This means that you’ll have much less of a pressure drop when you’re running more than one fixture at the same time, and you’ll get hot water to your fixtures faster. You can also install shutoff valves for every single line, so isolating a fixture can be done with ease.

Better water flow Instead of running large branch lines through the house and tapping off the branch lines with smaller lines to feed bathrooms, kitchens, and other rooms, PEX can be configured in what’s referred to as a ‘Home Run’. This is done by installing a large manifold in the basement near where the water comes in to the house, and then running a separate water supply tube to every single plumbing fixture. This means that you’ll have much less of a pressure drop when you’re running more than one fixture at the same time, and you’ll get hot water to your fixtures faster. You can also install shutoff valves for every single line, so isolating a fixture can be done with ease.

Of course, a home run can be installed with any type of water distribution system, but the extra time and cost needed for most other systems typically prevents this from happening. Oddly enough though, I rarely see home runs installed with PEX.

Less prone to failure Most failures with water supply pipes happens at the fittings, not in the piping itself. With PEX, there are far fewer fittings needed because the material is so flexible. Because PEX is so flexible, it is also freeze-break resistant. In the last several years I’ve seen a ridiculous amout of burst copper tubing from freeze damage, but I’ve never seen freeze damaged PEX tubing. PEX is also highly resistant to chemical damage.

If you decide to use PEX for your next plumbing project, plan to spend a little time getting trained on how to install it. The methods for installing PEX tubing vary between manufacturers, and anyone installing PEX tubing is supposed to be certified by the manufacturer. To get certified, check with the retailer you’re buying the PEX from. The manufacturers of PEX tubing give free certification classes on a regular basis.

Reuben Saltzman, Structure Tech Home Inspections – Email – Minnesota Home Inspections